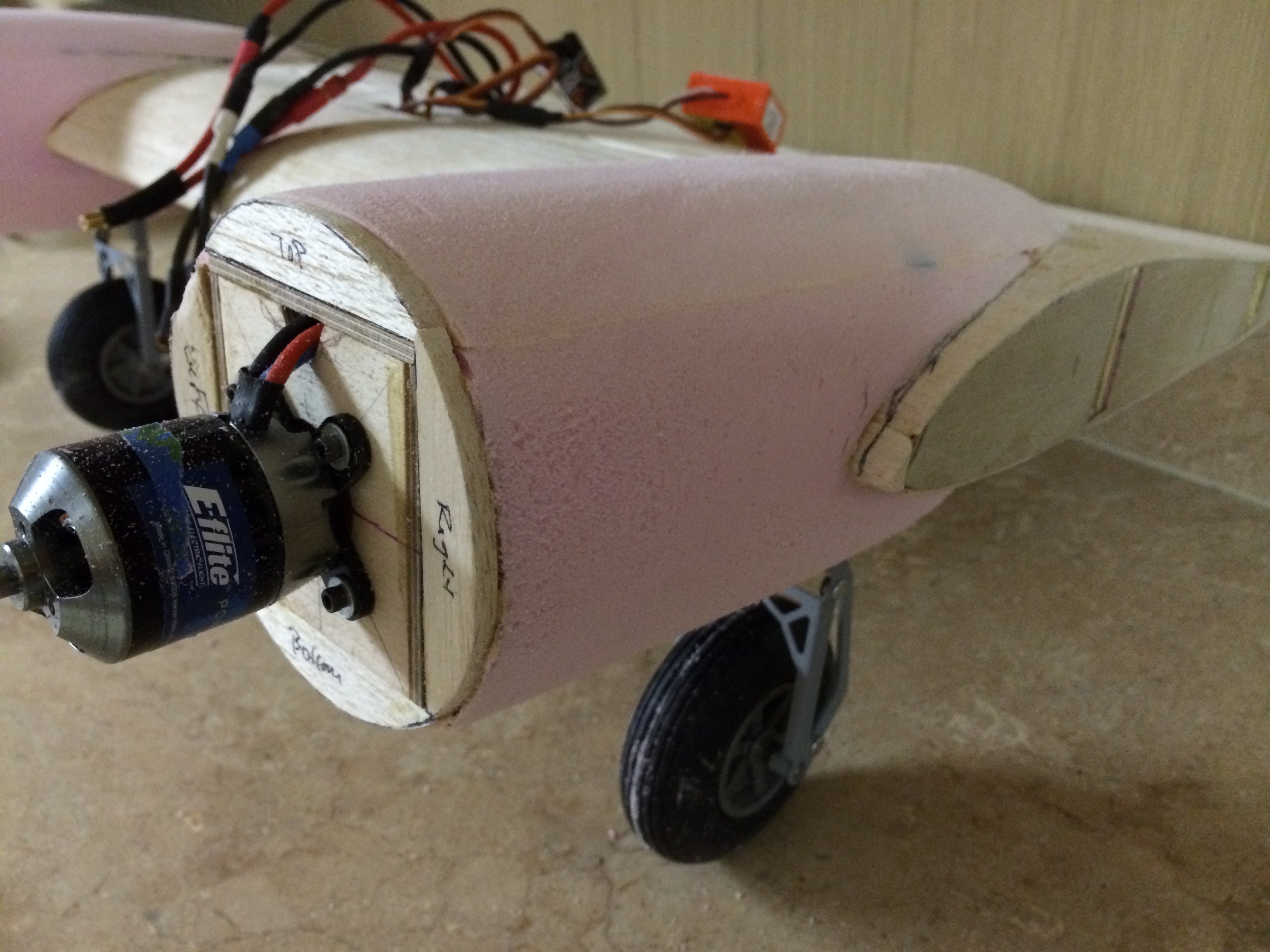

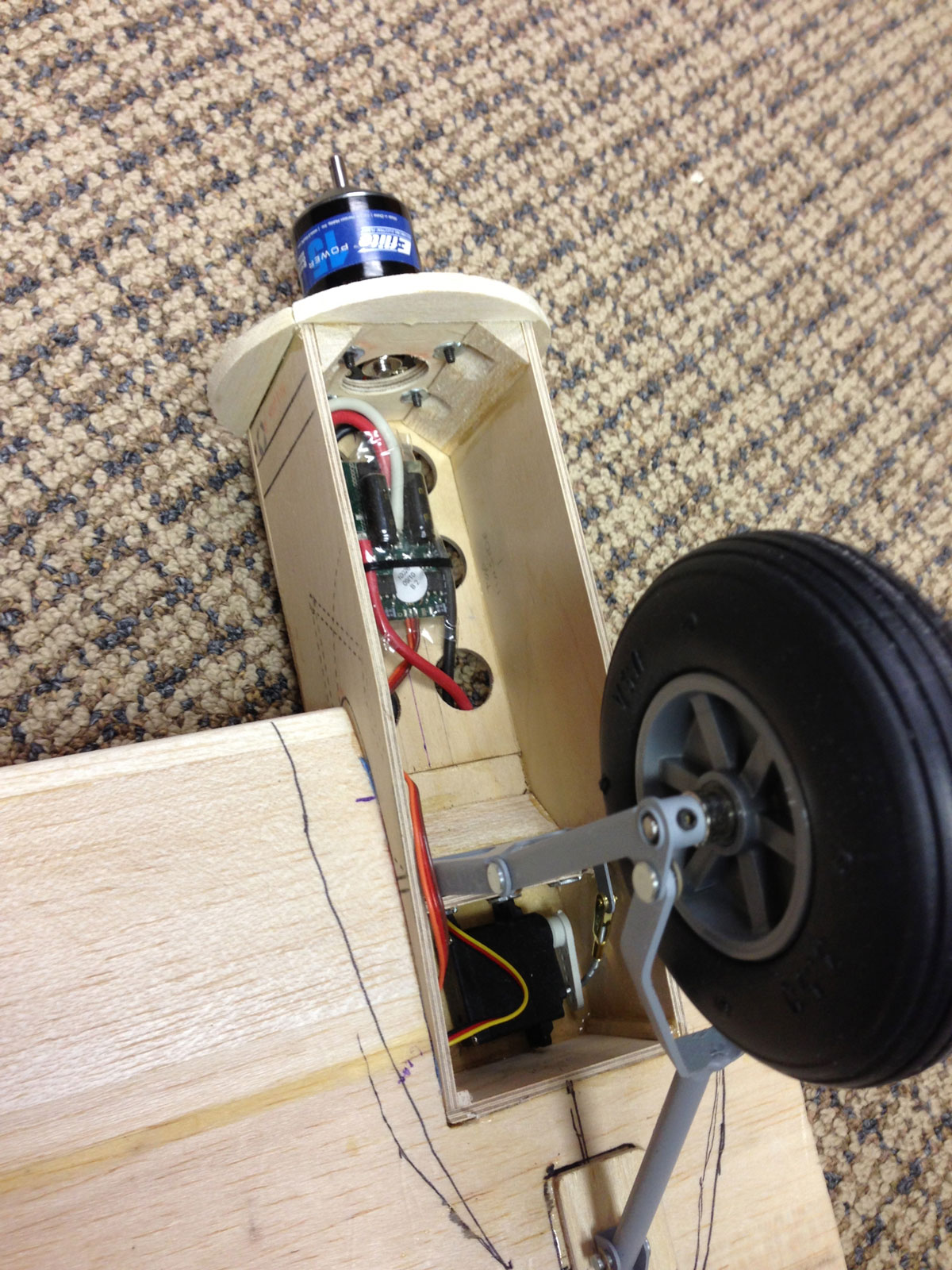

Real DC-3 airplanes are powered by two Wright R-1820 Cyclone radial piston engines. The radio controlled model I am building is powered by two E-Flite Power 15 electric motors housed inside two round engine covers known as cowls. I am cheating a little by using a pre-moulded part but honestly it didn’t save me too much time. What you get are 6 pieces o thin PVC that have to been cut out, clued together, patched up and then fiber-glassed. Not really a time-saver but that is what I did.

Each of the steps was pretty straight forward. I used a Dremel tool to sand out the extra flashing material that is part of the molded parts. The rounded cowl halves include a “tab” that is used to glue the pieces together. I used 5 minute epoxy to glue the joints. Next, I mixed up some Bondo type material and flared the seams . After it hardened, I sanded it smooth to the joint. After that, I used some 1.5 ounce Fiberglas cloth and some finishing resin to lay over the joint to provide a better finish and extra strength. After drying for a day I was able to use some medium fine grit sandpaper to sand off the excess finishing resin and get a nice smooth finish. Next will be a little fine sandpaper and then it will be ready for some primer.

Here is some pictures of the process:

- Picture from Top Flite DC-3 Manual

- Picture from AA Berry http://www.modelflying.co.uk

- Picture from AA Berry http://www.modelflying.co.uk